In today’s rapidly evolving manufacturing landscape, efficiency is crucial for businesses aiming to stay competitive. With technological advancements, Computer Numerical Control (CNC) machines, such as the CNC metal lathe, have become a staple in the metalworking industry. These machines offer high precision, reduced manual labor, and the ability to handle complex designs, making them indispensable for various applications in automotive, aerospace, and more industries. However, optimizing their performance to maximize productivity and minimize operational costs is the real challenge.

Improving CNC metal lathe service efficiency isn’t just about having the latest equipment. It involves fine-tuning processes, ensuring proper machine maintenance, and continually upgrading skills. From minimizing downtime to enhancing operator training, this article will discuss five key strategies that can significantly improve CNC lathe metal services, ensuring that your business stays ahead of the competition.

What is CNC Lathe Metal?

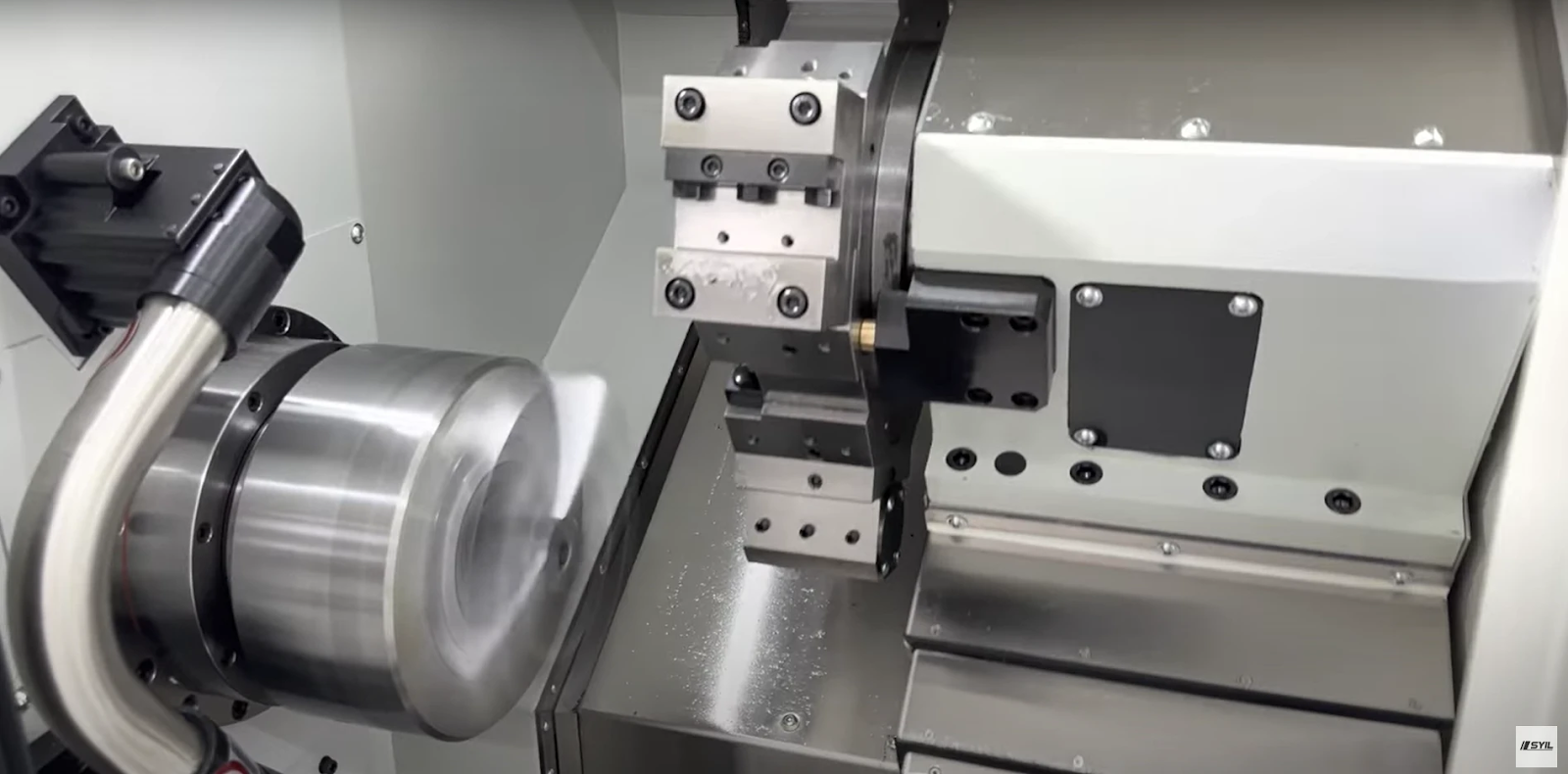

A CNC lathe is a sophisticated machine tool used to shape and machine metal workpieces by rotating the material against cutting tools. Unlike traditional manual lathes, which require constant operator input, computer software controls CNC lathe metal operations, which automates the movements of the tools and workpieces. This level of automation allows for greater precision and repeatability, which is especially useful in industries requiring high-quality parts and components.

CNC metal lathes are widespread across various sectors for machining different types of metals, including aluminum, steel, brass, and other alloys. The machines are designed to perform tasks such as turning, drilling, boring, and threading with remarkable accuracy, producing high-quality finishes and maintaining tight tolerances. As industries increasingly demand custom parts with intricate geometries, CNC metal lathes have become an essential part of the modern manufacturing toolkit.

The benefits of using CNC lathes go beyond just automation. They offer superior control over the machining process, allow for multitasking, and can be set up to perform continuous operations without manual intervention. These advantages make CNC lathe metal machines a top choice for manufacturing operations, prioritizing speed, accuracy, and flexibility.

How to Improve CNC Metal Lathe Service Efficiency

Maximizing the efficiency of CNC metal lathe services involves more than just routine maintenance; it requires strategic adjustments to equipment and processes. By focusing on key areas such as reducing downtime, optimizing tool management, and refining machining techniques, productivity can be significantly enhanced, leading to better results and lower operational costs.

- Implement Preventive Maintenance Programs

Regular maintenance is essential for any CNC machine, but implementing a preventive maintenance program takes it a step further. Preventive maintenance focuses on regularly scheduled inspections and servicing to identify potential issues before they escalate into serious problems. This proactive approach minimizes unplanned downtime, ensures the machines operate at peak performance, and extends the equipment’s lifespan.

For CNC metal lathe machines, preventive maintenance tasks might include checking for tool wear, lubricating moving parts, tightening loose components, and monitoring the condition of the electrical and hydraulic systems. Maintaining a detailed maintenance log can also help track the frequency of issues and predict when certain parts may need replacement, reducing unexpected downtime and keeping operations running smoothly.

Regularly inspecting cutting tools and monitoring machine conditions in real-time can also prevent sudden failures that could lead to costly repairs or lost production time. Establishing a preventive maintenance culture within the organization fosters a proactive approach to machine upkeep and significantly improves service efficiency.

- Optimize Tool Management

Efficient tool management plays a pivotal role in CNC lathe metal operations. The cutting tools’ choice and condition can significantly affect machining time, surface finish, and overall efficiency. Ensuring that tools are properly sharpened, calibrated, and stored in a well-organized system minimizes time spent searching for the right tool and reduces tool-related delays.

Using advanced tool monitoring systems that detect tool wear and breakage in real-time allows operators to replace tools promptly and avoid producing defective products. This enhances quality control, reduces scrap rates, and improves overall efficiency. Additionally, selecting the appropriate tool materials and coatings for specific metal types ensures optimal cutting conditions, leading to smoother finishes, faster machining speeds, and extended tool life.

Standardizing tool selection based on the type of metal cnc lathe operations performed can also help streamline processes. Establishing guidelines for when to use specific tools and under what conditions can improve consistency in machining results and reduce unnecessary tool changes.

- Minimize Setup Time

Setup time refers to the duration required to prepare a CNC metal lathe for a new task, which includes changing fixtures, loading programs, and calibrating tools. Reducing this time directly contributes to higher machine availability for actual machining, increasing productivity. Several methods can be employed to streamline the setup process:

- Standardizing Workflows: Develop standard operating procedures (SOPs) for common tasks, allowing operators to follow consistent setup steps. SOPs can be continually refined based on operator feedback to ensure maximum efficiency.

- Quick-Change Tooling: Implementing quick-change tool holders and fixtures can drastically reduce the time spent swapping tools and workpieces. This approach minimizes downtime and boosts productivity, especially when frequent tool changes are necessary.

- Offline Programming and Simulation: Create CNC programs offline and use simulation software to visualize and optimize machining operations. Identifying potential issues before running the machine helps prevent errors and reduces the need for extensive on-machine programming adjustments.

Investing in technologies such as automatic tool changers can also reduce setup time, allowing for uninterrupted production and improving overall service efficiency.

- Enhance Operator Training

The efficiency of CNC metal lathe operations largely depends on the skill level of the operators, even with advanced machines. Well-trained operators are more adept at identifying potential issues, optimizing machining parameters, and performing quick troubleshooting, directly impacting productivity. Investing in regular training programs ensures that operators stay up-to-date with the latest industry practices, machine technologies, and safety standards.

Training should encompass the technical aspects of operating the CNC lathe metal machines and best practices for maintenance and safe working conditions. Operators should understand the importance of consistent tool monitoring, appropriate parameter selection, and adherence to preventive maintenance schedules. Additionally, training operators on advanced machining techniques like adaptive control and high-speed machining will enable them to make real-time adjustments that can further improve efficiency.

Creating a culture of continuous improvement and encouraging knowledge-sharing among operators can also foster a proactive approach to problem-solving. This environment allows operators to learn from one another’s experiences, leading to more efficient processes and a better understanding of the equipment.

- Utilize Advanced Machining Techniques

Incorporating advanced machining techniques can significantly enhance the performance and efficiency of CNC metal lathes. These techniques include high-speed machining, dry machining, and adaptive control, each of which can optimize the machining process in different ways:

- High-Speed Machining: High-speed machining involves using higher spindle speeds and feed rates to reduce cycle times and improve productivity. It can produce better surface finishes and extend tool life by minimizing tool contact time when done correctly.

- Dry Machining: This technique reduces or eliminates the use of coolant in certain machining processes, cutting costs and reducing environmental impact. Specialized tools and coatings are required to handle the higher temperatures associated with dry machining, but the potential benefits of cost savings and reduced cleanup are substantial.

- Adaptive Control: Adaptive control systems automatically adjust machining parameters in real time based on the cutting conditions. They can maintain optimal cutting speeds and feed rates by continually monitoring variables such as tool wear, spindle load, and vibration levels, prolonging tool life and reducing cycle times.

These techniques can help manufacturers optimize CNC lathe metal services, making the processes more sustainable and cost-effective. As technology evolves, staying informed about the latest advancements and incorporating suitable machining strategies will enable businesses to maintain a competitive edge.

Conclusion

Improving the efficiency of CNC metal lathe services requires a holistic approach that combines preventive maintenance, optimized tool management, minimized setup time, skilled operators, and advanced machining techniques. By focusing on these key strategies, manufacturers can maximize productivity, reduce costs, and ensure consistent quality in metalworking operations. Implementing these practices not only extends the lifespan of equipment but also positions businesses for long-term success in the competitive manufacturing landscape.

CNC lathe metal machines have the potential to transform metalworking processes, but their full benefits can only be realized through careful planning and strategic management. Companies that embrace these strategies can effectively harness the power of CNC technology, achieving higher precision, faster production times, and greater overall productivity in their metalworking operations. As the industry continues to evolve, staying proactive in seeking ways to improve efficiency will ensure that CNC metal lathe services remain a vital part of modern manufacturing.